What we do

Objectives

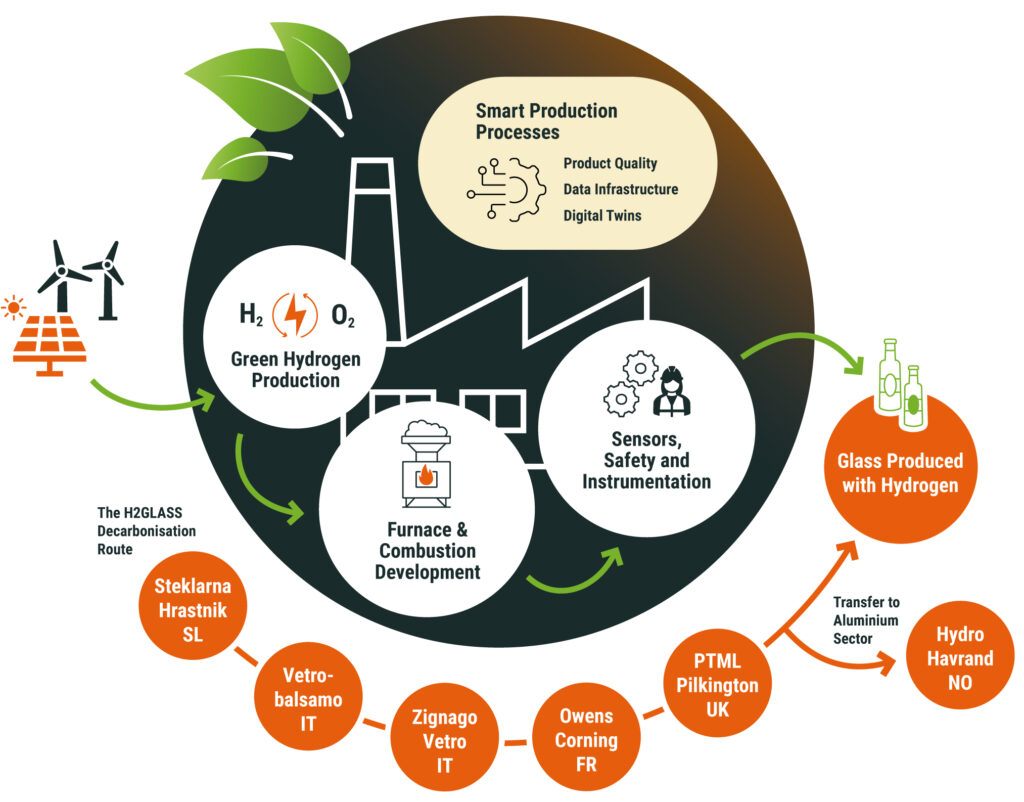

Develop the technology stack that will enable 100% H2combustion in the glass industry;

Validate H2GLASS technology through application in industrial context;

Prove economic and environmental viability of H2GLASS solutions compared to fossil fuels;

Develop IT architecture for automatic control and management and more efficient industrial processes;

Raise public understanding on H2 technology as solution for decarbonising industrial processes;

Transfer technology to other EU energy-intensive industries.

Methodology

1. Technology foundation

Develop specific furnace systems with improved heat transfer efficiency and minimal emissions

Adapt factory infrastructure to H2 process integration

Optimise mixed use of fossil fuels and H2

2. Digital Twin Technology for management & control

Develop new models and algorithms for automatic control of combustion system and furnace

Implement measurement instruments and imaging techniques to monitor H2 flames

Develop required big data infrastructure for data storage and analysis

3. Testing and validation of H2GLASS technology

Testing of H2GLASS technology in 6 Industrial demonstrators supplied with H2 by a portable electrolyser

Including one Industrial demonstrator representing the EU Aluminium Industry to test transferability of H2GLASS solutions to other energy-intensive industries

Assessment of technological, economic and societal impacts of green H2 compared to fossil-based fuels

Introduction Video

Project Timeline